EV Charging Contractor

Boring Subcontractors - EV Charging Contractor

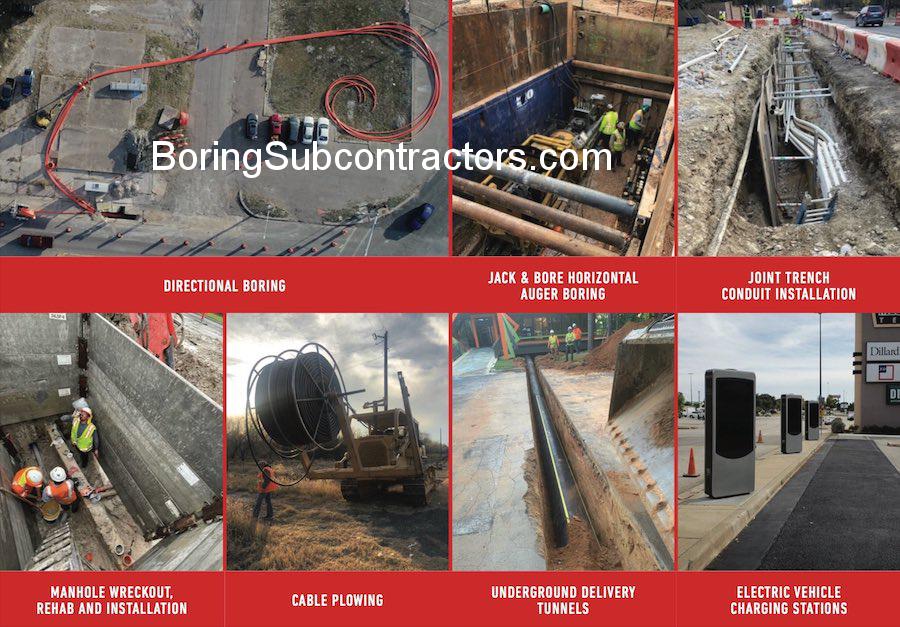

An EV (Electric Vehicle) Charging Contractor utilizes horizontal directional drilling (HDD), trenchless technology, and boring methods to efficiently install the electrical infrastructure required for EV charging stations. Here’s a detailed explanation of how these methods come into play:

Boring Subcontractors - EV Charging Contractor Companies

1. Horizontal Directional Drilling (HDD)

- What is HDD? HDD is a trenchless method for installing underground pipes, conduits, or cables with minimal surface disruption.

- Application in EV Charging

- Underground Conduits for Power Cables: HDD is used to install conduits beneath roads, sidewalks, or parking lots where surface disruption is undesirable.

- Long-Distance Cable Runs: For EV chargers located far from the main power supply, HDD allows contractors to lay power cables over long distances efficiently.

2. Trenchless Technology

- What is Trenchless Technology? This includes a range of methods like HDD, pipe bursting, and micro-tunneling that avoid digging large trenches.

- Application in EV Charging

- Avoiding Surface Damage: Trenchless methods are used to protect existing infrastructure, landscaping, and urban environments while laying cables or pipes.

- Reducing Installation Time and Costs: Minimizing surface restoration work speeds up the process and reduces costs.

3. Boring Techniques

- What is Boring? Techniques like auger boring or jack-and-bore are used to create horizontal holes or tunnels underground.

- Application in EV Charging

- Crossing Obstacles: Boring is employed to cross barriers like railways, busy highways, or rivers when laying power cables for EV stations.

- Precision in Placement: This ensures that power lines and conduits are placed exactly where needed, even in confined urban areas.

4. Electric Power Installation

- Power Supply for Chargers:

- Contractors connect EV chargers to the grid using cables installed through underground conduits.

- Power transformers, switchgear, and distribution panels are often integrated into the installation.

- High-Voltage Systems: For high-capacity EV chargers, contractors use heavy-duty cables installed through boring methods to handle increased power demands.

5. Advantages of Using These Methods

- Minimal Disruption: HDD and trenchless techniques avoid traffic disruptions, making them ideal for urban installations.

- Environmental Protection: Trenchless methods reduce the need for excavation, protecting the surrounding environment.

- Scalability: These methods allow easy expansion of EV charging networks without major surface-level modifications.

- Safety: Underground installation reduces the risk of accidents or tampering with cables.

Key Use Cases

- Public EV Charging Stations: Large networks of chargers along highways or urban areas.

- Fleet Charging Infrastructure: For commercial EV fleets requiring heavy-duty chargers with robust underground power systems.

- Residential and Workplace Chargers: Smaller installations in neighborhoods or office complexes, especially where aesthetic concerns matter.

Boring Subcontractors - EV Charging Contractor Near Me

By integrating these advanced construction and boring technologies, EV charging contractors can create efficient, scalable, and low-impact infrastructure to support the growing demand for electric vehicles.